Drilling a hole without a drill press can be challenging. There are several tricks to help you achieve the best possible results, though.

Using a drill to make holes in wood, metal, or other materials is an easy and convenient way to fasten pieces together or run electrical wiring.

Using a drill press is the best way to ensure that your holes are perfectly straight and true, but sometimes you don’t have access to one. If you need to drill a straight hole without a drill press, simply use a hand drill.

When you’re only drilling one hole, it’s hard to justify the expense of a drill press. But you can drill straight holes with a hand drill if you follow these three steps.

Table of Contents

How To Drill a Straight Hole without a Drill Press?

Create a Marker

Before you start. As with many projects that require a hand drill, creating a mark in the surface that you are drilling will help guide you.

Select The Right Torque

The chuck where you insert your drill bit of choice has little marks on it that indicates the torque value of your drill.

Select Your Speed

You may not know this, but many drills come with adjustable speed settings. The higher the number, the faster your drill will go: Low numbers are usually selected when you are using larger bits and drilling through softer material (wood); medium numbers are used for general drilling, and high numbers are reserved for harder materials (metal) and smaller bits.

As always, safety first! Using safety goggles is required for this project. Clampdown whatever it is that you are drilling into so as not to ruin it from too much movement.

Also, remember to keep your work area clean and free from debris like sawdust or shavings, which could interfere with your project and make for an even more frustrating experience!

The chuck where you insert your drill bit of choice has little marks on it that indicates the torque value of your drill. Generally, drills will have a medium to high torque, but they are not created equal.

A higher torque is best for drilling through hard materials like metal, stone, and concrete. Lower torque is better for drilling into wood or plastic. If you use a lower torque setting to drill through harder materials, the bit will get stuck and could break or fly off the drill.

The speed settings on a drill are generally high or low. Low-speed settings are good because they give you more control over the drill and more control over the hole you’re making.

However, if you set your drill at too low of a speed, it won’t be as effective at cutting through whatever material you’re working with.

Tip

If you’re unsure about what speed to use for your project, ask an associate at The Home Depot for help choosing the right one for your job.

How Do You Make a Straight Hole Without a Drill Press?

This is a situation where you have to be very careful. Making a straight hole only looks like it should be easy, but drilling a straight hole with a hand drill isn’t as easy as it looks.

If you’ve ever tried to do this, you’ve probably ended up with something that looks more like an arc than a straight line.

How can you get around this problem? One option is to buy or borrow a drill press and use that instead of your hand drill. But what if you can’t afford the machine or don’t want the hassle of borrowing one?

Fortunately, there are other ways to get your job done. Here are some tips on how to make a straight hole without a drill press:

Use a vice to hold the material in place while drilling. Make sure it’s tight so that the material doesn’t wiggle at all as you’re drilling.

Mark the spot where you’ll put the hole using a fine-point marker or other object that makes a small dot or scratch in the surface of your work piece (such as an awl).

Make sure that the bit is perfectly vertical when you start drilling — don’t tilt the bit or guide it into place. Resting your elbow against something immovable can help with this since your hand will get tired of drilling at times.

How Do You Drill a Straight Hole With a Hand Drill?

A drill press can be handy, but it’s not the only way to make a square hole. For example, you can use a hand drill with the help of a few accessories.

- Draw a line on the wood parallel to your baseline. This is where you’ll drill your hole, so make sure it’s far enough from your baseline to accommodate for any mistakes or misalignments.

- Clamp your workpiece to your workbench in such a way that at least part of the line you drew is overhanging the edge. This way you’ll be able to mark both sides of the hole with your pencil and verify if they’re aligned.

Now take one clamp and put it over the line on top of the workpiece. Make sure that when you tighten this clamp its jaws are absolutely parallel to each other and perpendicular to the edge of your workpiece (hold a square against them).

Use another clamp to hold down one end of your ruler in such a way that its edge is aligned with one side of your ruler.

What Can I Use if I Don’t Have a Drill Press?

To make a straight hole without a drill press, you’ll need three things:

- A vise to hold the wood in place.

- A clamp to lock the ruler in place.

- A long ruler or measuring stick, which will act as your guide.

The process itself is fairly simple. Clamp your ruler along one edge of the workpiece, then set your drill at a right angle to it. Use a square or T-square to ensure that you’re drilling at a 90-degree angle to the guide.

Once everything’s in place and you’re satisfied with the alignment, drill through one side of the work piece, then flip it over and drill from the other side to complete the hole.

How Do You Drill a Hole In a Straight Line?

You can drill a straight hole on any flat surface. Getting straight drilling in the middle of a piece of wood is easy. Taking the following steps will ensure you get a straight hole every time.

- Mark your drill point or center point with an awl.

- Using an awl to make an indentation makes it easier to see where you need to drill and it keeps the bit from wandering when you start drilling.

- Make sure the surface is flat and level.

- Use a hanging bubble level to check that your table or surface is perfectly level before starting. If your surface is not level, your holes will be crooked and not straight.

- Install a new bit (if using one).

If using a used bit, inspect it for cracks, chips or other damage. If you are using a new bit, make sure the shank fits properly in your chuck. The shank should be smooth and not have raised edges from tapping against other bits in storage.

It should spin freely without wobbling or wiggling side to side. It should also be clean; no oil or grease from storage should be present on the shank or threads.

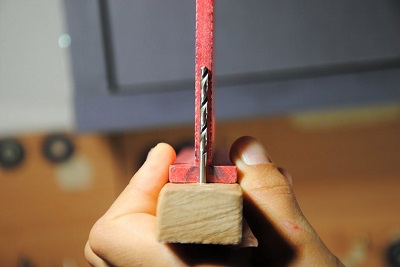

While it is not a perfect solution, you can use support that the drill bit slides into. This gives you more control and less chance of your hand slipping.

Broadly speaking, the most common supports are:

Parallel Support

The support pushes the drill perpendicular to the surface of the piece. This way, it will be possible to do straight holes on both sides of the wood.

Guide Support/Drill Guide

The drill guide allows you to keep the drill parallel to the surface by guiding it along its axis. Of course, this means that you will only be able to do straight holes on one side of the wood.

How To Use a Drill Press To Drill Straight?

A drill press is a staple in any woodworking or metal shop. It allows you to drill straight through wood or metal at a variety of depths with ease, making it perfect for drilling holes for dowels, bolts, screws, and more.

A portable drill guide is an accessory that attaches to the chuck of your power drill, ensuring that the hole you drill is perfectly straight. It also helps prevent slippage while drilling, which can be dangerous.

Drilling a hole with a cordless drill is easy, but the real skill lies in the preparation work. A clean, flat surface is a must before starting to drill.

An angle attachment can be used to attach an angle plate to your drill press. This allows you to mount more than one piece of material at a time, giving you more flexibility when working on projects like cabinets and shelves.

How To Use a Portable Drill Guide?

When using a drill press, there are several things that you need to consider. Some of these include:

The Type of Drill Press You Have: There are two main types of drill presses: those that sit on top of your table and those that sit on the floor. You should be aware of which type you have so that you can easily identify it when drilling holes into materials.

The Size Of Your Drill Press: Some people prefer smaller size presses over larger ones because they can fit them under their table or desk. On the other hand, some people like larger size presses because they take up less space in their workshop or garage. The size of your drill press will depend on personal preference as well as how much room you have available for it in its intended location.

Can You Drill Straight Into a Wall?

Drilling straight into a wall is pretty easy. You don’t need to worry about it being level, because you want it to be perpendicular to the wall. If you’re drilling horizontally, hold your drill square to the wall and keep it level. If you’re drilling vertically, hold the drill flat against the wall and make sure it’s not tilted.

If you have a spade bit that’s wide enough for your drill chuck, chuck it up and go for it. If it won’t fit in your chuck, clamp a board to the wall so that its edge is exactly where you want the hole to run through. Then drill through the board until you’ve cut all the way through with your spade bit.

You can use a router as a drill press if you’re willing to do without some of the benefits of using a router table — like cutting shallow mortises or rabbets or using jigs and guides.

To use a router as a drill press, clamp a board down tightly on top of your router table and put your workpiece underneath so that you can drill straight down through it. You’ll probably want to use an edge guide or fence so that your bit goes exactly where you want it.

How Do You Drill Straight With a Spade Bit?

Once the pilot hole has been drilled, use larger diameter bits to enlarge the hole until your desired diameter is reached. If you don’t have multiple bits in different diameters, a spade bit works well and requires no center punch.

Spade bits have no center point to guide them, so they tend to wander if not properly controlled and guided by hand, but they work well when used with pilot holes because they follow the path of least resistance.

Frequently Asked Questions

1. Can You Use a Router As a Drill Press?

The router is not designed to be used as a drill press, so I wouldn’t recommend it. You can use a hole saw if you have one available, but it will take some time and some practice!

2. How Do You Tap a Straight Hole By Hand?

You can tap a straight hole by hand by using a tap wrench (or tap socket) and rotating the tap while applying pressure.

3. Is It Easy To Drill Holes With a Cordless Drill?

A cordless drill is not ideal for drilling holes due to its instability and the fact that it may be inconvenient to use it in tight spaces.

Wrap Up

The best way to drill a straight hole is to use a drill press. If that is not an option, there are two other methods.

One is to use a brad-point bit and a special jig that rides on the edge of the wood to guide the bit. The only problem with this method is that you can’t see what you are doing.

The second method is to use a spade bit and guide it with your left hand while turning the brace with your right. This works fine in softwoods such as pine, but it doesn’t work in hardwoods unless you use a special technique.