Aluminum is widely known for its strength, durability, and heat resistance.

In addition, it’s lightweight, corrosion-resistant, conductive, and affordable!

For that reason, aluminum material is used in many items, ranging from household hoods and airplane parts to electrical goods and beyond.

There’s a good chance that most cookware in your home is made up of aluminum!

What we’re trying to say is that aluminum plays a very important role in our daily lives.

However, even with its high strength, aluminum can sometimes break.

What happens then? Do you just throw it away?

In Hurry! Then Check Our Editor’s Recommendations:

Of course not! You just need the best epoxy for aluminum and glue the components back together!

There is one big challenge, though! Not all epoxies work for aluminum! Therefore, you need to be very cautious when choosing epoxy for aluminum, otherwise, you may end up wasting your money.

You don’t want that, right? We don’t want that either. That’s why we’ve done the hard work for you to bring you nothing but the best epoxies that are specifically designed for aluminum. Besides, you can rest assured, each of these epoxies guarantees a durable bond.

With that in mind, let’s have a look at these epoxies and what makes them so great!

Table of Contents

10 Best Epoxy For Aluminum Reviews

1. Hy-Poxy Alumbond Aluminum Putty Repair Kit

Just as the name ‘alumbond’ suggests, this epoxy is specifically designed for aluminum repairs. That alone is enough to make it top our list. It’s also considered to be the best aluminum repair epoxy.

So, whether you’re working on a large aluminum repair task, this repair kit from Hy-Poxy is a great option.

You can also use it to seal holes in aluminum components or any other metal surface. No wonder, it’s loved by most mechanics and plumbers out there.

This 2-part epoxy has an 8600 PSI compression strength and 3500 PSI. Therefore, you can use this sealant in many areas including valves, HVAC pipes, boat hulls, tanks, and more. It’s also worth noting that its temperature resistance is at 250 degrees F.

Its formula has pure aluminum particles and other additives like curing agents that provide extra strength and durability to the repaired surface.

Applying this putty is very simple, but first, make sure the surface is properly cleaned. You can now pour the 2 contents on the aluminum surface, where you can mix them together.

As for the mixing ratio, take an equal amount of hardener and resin from each tube. This should be done for about 3 minutes.

After application, leave the epoxy for about 45 minutes for it to dry completely and strengthen the damaged surface.

This sealant creates an extremely strong bond, so you don’t even have to weld the surface.

Once the epoxy cures fully, you can now sand, paint, or drill the surface. It will leave you with a rust-resistant aluminum gray color, even after polishing or sanding the surface.

Pros

- Fast setting and drying time

- High tensile strength

- Convenient application

- Ideal for various applications

Cons

- Mixing requires effort

2. J-B Weld SteelStik Steel Reinforced Epoxy Putty

J-B is an extremely popular brand in the adhesive industry, thanks to its high-quality sealants. One of their top-rated and best-selling model being this J-B Weld 8267 epoxy.

So, feel free to use this epoxy putty to glue damaged aluminum components together. It offers a quick solution that creates a rust-resistant, strong bond!

Another good thing that has made this epoxy so popular is that it’s very affordable. Even better, it works with all types of metals.

You can use it on aluminum, stainless steel, bronze, copper, brass, and iron. Whether you want to repair household or automotive components, this epoxy will get that task done!

Applying this putty is simple as well. Just take it out and cut the amount that you need. Since the product is a 2-part component, you need to mix them together. This can easily be done by hand. After that, you can now apply it to the aluminum surface.

One unique thing about this sealant is that it is available on a stick. This allows you to store the unused putty conveniently for future use.

You’ll love how fast this formula sets and cures. This is because it sets in 5 minutes and dries in less than an hour after application.

When it cures, it forms a dark gray color that works well with many surfaces. You can now sand, tap, or drill it!

With a 900 PSI tensile strength, this epoxy forms quite a strong bond when it sets. This indicates that any component joined with this epoxy will not break off easily, even when subjected to high loads.

Furthermore, it can withstand a maximum temperature of up to 300 degrees F after curing, making it the best high temp aluminum epoxy on this list.

Not to forget that it can resist damage from chemicals like petroleum and hydraulic fluids.

Overall, this epoxy putty stick is ideal for both large and small projects. It will restore the strength of your aluminum surface and ensure superior performance.

Pros

- Creates a strong bond

- High temperature resistant

- Fast setting and drying

- Super affordable

- Works on a wide range of metals

Cons

- The tensile strength is not that great

3. Permatex PermaPoxy Steel and Metal Epoxy

This PermaPoxy is the other great epoxy that you can use to repair or bind aluminum components. Besides, it’s very versatile and strengthens most metal surfaces that you can think of.

Some of these metals include; brass, chrome, iron, steel, stainless steel ad copper among others. But best of all, PermaPoxy eliminates the need for brazing or welding the surface!

Just like the other sealants we have listed above, this epoxy is extremely easy to apply. It’s a 56-gram epoxy that comes in a 2-part plunger. These tubes have a convenient design that ensures you dispense out equal amounts of epoxy.

Besides, the tubes are re-sealable, meaning you can save some epoxy for future use.

The package consists of 1 hardener bottle and 1resin bottle. Therefore, the application of this epoxy involves the mixing of these parts.

When applied, this adhesive sets in 4 minutes, but takes 24 hours to cure fully, forming a dark grey finish that can be shaped, filled, or drilled.

After that, it will be able to withstand temperatures ranging from -60 to 300 degrees F. This eliminates the risk of shrinking and cracking when subjected to various environmental factors.

It also has an unmatched tensile strength that enables it to resist pressures of up to 4,500 PSI. As if that’s not enough, this epoxy is waterproof, making it both solvent- and water-resistant.

The only issue with this epoxy is that it has some smell that makes its application a little unpleasant. Other than that, it’s the best epoxy for aluminum components and other metal surfaces.

It’s a great option when you’re working on complex projects involving multi-piece assemblies.

Pros

- Fast setting & drying time

- Easy application

- High tensile strength & heat-resistance

- Ideal for repairing and binding aluminum and other metal surfaces

Cons

- Has an unpleasant smell

4. J-B Weld MarineWeld Epoxy

As you know, the lightweight nature of aluminum makes it a perfect option for the marine industry including things like boats. Unfortunately, such objects tend to have leaks and holes over time.

Understanding that, J-B Weld created an epoxy specifically designed for such items that come into contact with water.

Hence the name ‘MarineWeld’! With this epoxy, you don’t need to be concerned about welding the damaged aluminum surface.

However, we don’t recommend using this epoxy in parts that remain underwater.

This sealant gives water-sport and boating enthusiasts an affordable way of filling gaps in their boats.

Even better, the epoxy sets in 4 to 6 hours at ambient temperature. It takes 15 to 24 hours to cure, leaving a dark gray color on the surface.

What makes this epoxy works well on marine objects? Well, that would be its excellent ability to resist saltwater, oils, acids, chemicals as well as other corrosive materials.

Moreover, its ability to tolerate extreme temperature variations after curing is incredible!

It’s very versatile, meaning you can conveniently use it on various components like a deck, hull, engine, and more. Even better, you can use it for different materials like fiberglass, wood, composite, aluminum, and more.

Similar to any other 2-part epoxy out there, this adhesive should be mixed in the 1:1 ratio. Doing so triggers a chemical reaction that converts the mixture into a hard and tough compound like steel.

While mixing the resin and hardener might seem like a difficult task, applying this adhesive is quite simple. In fact, even beginners can easily use it without any professional help.

It’s also worth noting that this industrial-strength adhesive features a tensile strength of about 3,960 PSI on curing. Not to forget that you can paint, sand, drill, or even shape it the way you want.

To sum it up, this adhesive is a great investment since it offers a durable bond that is as strong as steel. Also, it’s ideal for both big and small buildings as well as reconstruction projects.

Pros

- Creates a strong permanent bond

- Highly versatile and reliable

- Water- and chemical- resistant

Cons

- Hard to remove from the skin

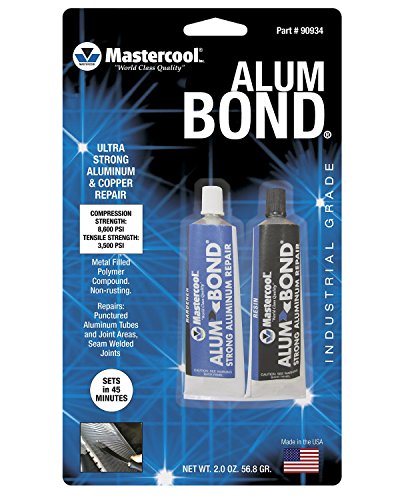

5. MASTERCOOL Alum Bond Repair Epoxy

Mastercool Epoxy is another great epoxy adhesive for repairing aluminum surfaces. Moreover, this 2-part epoxy is ideal for repairing other metal surfaces like copper as well. With this adhesive, you can rest assured that those holes on your damaged aluminum component will be long gone.

Although this epoxy will work on other surfaces, it’s specifically designed for aluminum. Something that you can see from its name ‘Alum Bond’!

Besides, its formula contains pure aluminum particles, dry-out agents as well as superior additives. This combination ensures that the epoxy provides maximum loading capacity and durability. Also, this increases its ability to withstand severe climate and weather conditions, line pressure, compression, and temperature changes.

To be precise, it can withstand a temperature of up to 205 degrees F, compression strength of up to 8,600 PSI, and tensile strength of up to 3500 PSI. Therefore, you can use this adhesive for various applications. For instance, it’s ideal for repairing pumps, valves, condenser coils, and even radiators.

When it comes to application, you follow the same steps as with other similar 2-part epoxies. So, start by mixing the 2 components in a ratio of 1:1 for about three minutes.

Then place the resulting mixture on the prepared aluminum surface. Cover every hole and crack properly and leave it for about 45 minutes to set.

You can now let it dry completely which takes about 5 hours. After that, your surface will have a durable, rust-resistant aluminum finish.

Pros

- Fast setting & curing time

- Wide range of applications

- Creates a long-lasting bond

- Withstands severe environmental conditions

Cons

- It’s a bit expensive

- Needs an extremely clean surface

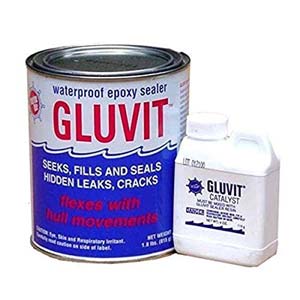

6. Travaco Marine Waterproof Epoxy for Aluminum Boat Repair

Manufactured by Travaco, Gluuvit RM330K epoxy is another great adhesive for sealing aluminum surfaces. Thanks to its marine-grade formulation that seals and fills leaks and leaks effectively.

Moreover, its seal forms a hard protective coating that bonds well with the boat’s hull, decks, and cabin.

And when you mix it with the included Gluvit Catalyst, it gives you an incredible epoxy sealant. That way, you can use it to seal hairline cracks and extremely small holes!

In terms of packaging, this adhesive comes with 2 products; Gluvit catalyst and epoxy sealer. The sealer is available in a big 1.8 lbs can, while the catalyst (hardener) comes in a small 0.268 lbs. bottle.

So, before you apply this epoxy sealer to your aluminum surface, you need to mix these substances. Luckily, the can is half full of resin, giving you enough space to combine these parts with ease. Once you’ve done that, use a roller brush to spread the mixture uniformly over the surface.

After applications, the sealant will take about 48 hours to cure. Although this may seem like an inconvenience, the extended curing time ensures that it penetrates deep into cracks to toughen and seal.

More notably, this gives it the exceptional ability to protect aluminum from water and galvanic corrosion.

Overall, RM330K is considered the best epoxy for aluminum boat repair since that’s what it’s specifically designed for. However, you can use it on other surfaces apart from aluminum. As an example, you can apply it to steel, fiberglass as well as wood.

Pros

- Easy application

- Paintable & sandable

- Suitable for use on aluminum, wood, steel, and fiberglass

- Resistant to mold/mildew and abrasion

- Minimizes the risk of galvanic corrosion and water absorption

Cons

- Takes 48 hours to harden

- Doesn’t dry completely clear

7. Blue Magic Epoxy Putty Metal Repair

Aluminum material has many uses in our homes, due to its ability to resist corrosion. For instance, it’s used to make water tanks, utensils as well as cooking and food serving areas.

Yet, most aluminum epoxies aren’t safe for use on such surfaces since they may contain chemical ingredients. Well, this is where Blue Magic 16002TRI Quiksteel epoxy comes in!

Unlike most metal adhesives, this epoxy is both food-safe and water-resistant. For that, it’s ideal for use in aluminum dishwashing sinks and fixing water tank leaks. In addition to those properties, this formula has many unique features to offer.

For a start, it has incredible thermal resistance since it can tolerate temperatures of up to 25o deg F. Therefore, it’s safe to apply on areas that experience high heat like heat sinks, workshop heaters, and so on.

Also, unlike the 2-part epoxy we’ve looked at above, this product comes as a 1-part epoxy setting. This will help you save time since you don’t have to mix it with a hardener.

However, you need to warm it up before application to activate it. After application, it will take 5 minutes to set and about 1 hour to cure fully.

Once that happens, you’ll be left with a strong, durable surface. Even better, this epoxy adheres to many surfaces other than metal. Instead, it adheres to other materials such as plastic, PVC, wood, ceramic, and fiberglass.

Bottom line, if you want a 1-part epoxy for your metalwork project, Blue Magic 16002TRI will do the trick!

Pros

- Water-resistant and food-safe

- Fast setting & curing time

- Can be sanded, painted, or drilled on hardening

- Outstanding thermal resistance

- Works with all metals and many other surfaces

Cons

- Has an unpleasant smell

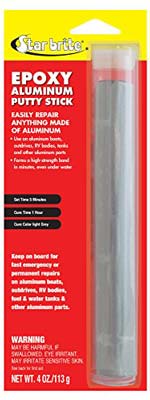

8. Star Brite Epoxy Aluminum Putty Stick

Star Brite epoxy putty stick is a great tool for making emergency and permanent repairs on metal surfaces.

More notably, it’s specifically designed for use on aluminum parts like water/ fuel tanks, outdrives, and aluminum boats. However, you can use it on other metal surfaces, wood, as well as plastic.

Why choose Star Brite epoxy stick?

At first glance, these epoxy putty sticks come as a 4 oz. hand kneadable material. However, it contains unique additives that enhance its adhesive properties to bond to aluminum components. On top of that, it forms high-strength bonds in minutes.

To be precise, this epoxy takes about 2 minutes to set after application. While its curing time is around 30 minutes, so it will not take much time as well. Best of all, it’s quite easy to apply. Simply cut the amount of epoxy you need from the putty stick, mix it up, and apply!!

Besides, you can even paint, sand, fill or drill it, one hour after application. But once it cures fully, it will maintain its shape. Even better, it can tolerate great pressure of up to 900 PSI.

Not to forget that it can easily withstand high temperatures of up to 250 deg F. Such properties make it the best aluminum adhesive for repairing drive units, mufflers, and more.

Lastly, this epoxy works well underwater. For that, you can use it to repair small cracks as well as stop leakages on boats.

The only drawback about this epoxy putty stick is that it may cause skin irritation. So, make sure you wear gloves when applying it, especially if you’ve sensitive skin.

Pros

- Forms a water-resistant coating

- Ideal for fast aluminum repairs

- Decent heat tolerance

- Great tensile strength (9000 PSI)

- Can be drilled, sanded, and painted

- Fast curing time

- Cures underwater

Cons

- May cause skin irritation

9. TotalBoat Marine Epoxy for Aluminum

As you know, fairing refers to making a surface uniform. Well, that’s exactly what this epoxy fairing compound from TotalBoat does!

For that, it’s a great product for filling in low spots in aluminum to make the surface even. More importantly, you can use it when the dents, gouges, holes, and voids are relatively shallow.

In essence, TotalBoat TotalFair fairing compound is a lightweight 2-component aluminum epoxy putty. Not to forget that it has incredible water-resistance properties.

Hence making it suitable for boat repairs below and above the waterline. Better still, it works on various materials including steel, wood, aluminum, and fiberglass.

When it comes to applications, start by mixing the resin (part A) and hardener (part B) components. Unlike most 2-part epoxies, these components are color-coded.

For instance, the resin is yellow, while the hardener is blue. Once you mix these components properly in a 1:1 ratio, this mixture will change to a green color. This indicates that adhesive is ready to be applied on the surface.

Still, on application, this formula is easy to apply on inclined or vertical surfaces. Thanks to the excellent sag resistance of the resulting product.

Even better, you can sand it after curing to make it smoother. Moreover, you can paint over it with epoxy, polyester, or latex primers. Note, TotalFair takes about 3 hours to cure fully at 80 deg F.

Moving on to the packaging, this epoxy kit comes with two 1-pint cans. However, it’s available in other size options like gallon and quart kits. Either way, you’ll get a plastic spreader to help you mix the components with ease.

Pros

- Fast-drying formula

- Easy-to-mix, color-coded components

- Works on inclined, overhead, vertical, and horizontal surfaces without sagging

- Adheres to aluminum, steel, fiberglass & wood

- Ideal for use below and above the waterline

Cons

- Doesn’t adhere to 1-component primers or paints

10. METALSET A4 Aluminum Epoxy Adhesive

Last on our list is this powerful aluminum epoxy adhesive from METALSET. A product that has been used by major automotive manufacturers and airlines for years. So, if you want a reliable epoxy for metalwork projects, METALSET A4 is such an incredible option!

That said, here are some unique properties this formula has to offer.

For starters, this product comes in 2 parts; resin and hardener. Specifically, the package includes 11 oz of part A and part B in squeeze tubes.

This makes them easy to mix and apply to the surface. Besides, the tubes easily dispense an equal amount of the components.

After that, thoroughly mix the components for 3 minutes until they form an even grey color. Then apply it to the prepared aluminum surface at a thickness of 0.08cm (1/32”) to 0.16cm (1.16”).

Next, place the other surface over the adhesive and use weights or clamps to apply uniform pressure. Thankfully, this formula isn’t runny, so you can apply it on vertical surfaces without sagging.

When it comes to curing, Metalset A4 takes about 16 hours to cure fully at room temperature. However, you can apply mild heat to help the epoxy cure faster.

For instance, the adhesive will take 2 hours to cure when subjected to a temperature of around 150 deg F.

Finally, this epoxy adhesive provides excellent adhesion to both non-porous and porous surfaces. For that, it’s ideal for use on metals, coated woods, plastics, and more.

However, make sure you clean and dry the surface before applications to ensure a successful bonding.

Pros

- Works on porous & non-porous surfaces

- Short curing time

- Mess-free applications

- Adheres to vertical surfaces without sagging

- Powerful & durable epoxy adhesive

- Resists solvents, alkalies, and dilute acids

- Good machine qualities on curing

Cons

- Requires surface preparation before application

What to Look For Before Buying the Best Aluminum Epoxy

Now that you’ve seen the 5 best epoxy for aluminum reviews out there, how do you choose the best one for you?

Sometimes, settling on a specific product is not that simple, especially when you’ve so many great options in front of you. However, everyone intends to use the adhesive for a certain task or need.

Therefore, you should always choose epoxy that is perfectly suited to your needs.

To accomplish that, there are some factors you should consider before you settle on the top aluminum epoxy. Some of these factors are:

Drying & Setting Time

Epoxies tend to vary significantly in terms of their setting and drying time. Some can take hours to set while others just take a few minutes. While that doesn’t affect the quality of an aluminum repair epoxy, it’s a very important factor.

For instance, if you’ve limited time, then you’ll need a fast-drying adhesive to get the task done quickly. On the other hand, if you’re not in a rush, the drying time may not be an issue.

Also, if you’re a beginner, we suggest that you go with an adhesive with a longer drying and setting time.

This is because it will allow you to change or adjust the position of the damaged aluminum components to get excellent results.

Temperature Range

Most epoxies tend to set at ambient temperatures. So, if the component is in an area that is too hot or cold, it might not cure properly.

With that in mind, it’s important to consider the type of temperatures or environment your aluminum component will be exposed to.

If the epoxy cannot withstand extreme temperature, it might end up being damaged. That’s why it’s always good to choose an adhesive that can withstand a wide temperature range.

Compatibility

Not all epoxies work with aluminum. In fact, some are designed to work on other materials like wood and plastic.

Therefore, before you choose a certain adhesive, make sure it’s compatible with aluminum surfaces.

Luckily, the best aluminum epoxy also works on other metals like stainless steel, brass, and copper among others.

Tensile Strength

You may have noticed that all adhesives on our list include details of their tensile strength. If you look at those strengths again, you’ll realize that different epoxies have different tensile strengths.

As we said earlier, everyone intends to use epoxies for different projects. Thus, you should consider the intended use of the adhesive to determine the adhesive with the ideal tensile strength.

For instance, if you’re working on a heavy-duty project, then you’ll need a sealant with a higher PSI strength and vice versa.

Application

Lastly, consider how simple applying the epoxy is, especially if you’re a beginner.

Most epoxies are not very user-friendly since they involve fussy mixing, running consistency and they dry out quickly. For that reason, it’s very important to select an aluminum epoxy that is easy to apply.

Frequently Answer Questions

This will depend on the brand and type of adhesive. Some aluminum epoxies tend to work on other surfaces like PVC, fiberglass, metals, and even wood.

However, there are those that only work on aluminum. Using epoxy on the right surface guarantees great performance and superior adhesion. So, avoid using aluminum epoxies on a surface that they’re not compatible with.

Start by abrading the surface with an 80-grit aluminum oxide sandpaper. Once you’ve removed all the old coating, blistering, chalking, and flaking, you can now apply the adhesive.

If the adhesive contacts your skin, try to remove it as soon as you can using vinegar. Drench a dry cotton cloth into vinegar and rub the affected area until it softens. You can remove it with ease.

Yes! Epoxy does a great job of covering cracks and holes on aluminum surfaces. It forms a tough component that strengthens the surface after curing.

First of all, you should know that not all aluminum epoxies are paintable. But, if you’ve used one that allows painting, it’s good to prime it, probably with a self-etching primer. The formula contains micro-etch chemicals that increase paint adhesion to the cured epoxy.

Conclusion

We have highlighted some of the best epoxies in the market at the moment. Their ability to bond aluminum components is unmatched and they’re extremely easy to use, even for beginners.

However, as we’ve said over and over again, not every epoxy might be perfect for you. That’s why encourage you to consider the intended use of the epoxy as you go through these reviews.

If you do that, you’ll definitely be able to choose a suitable sealant for your task and you’ll never regret it.

So, have a look at these aluminum epoxies once more until you find the perfect one for your job.

Remember, the best epoxy for aluminum should be water-resistant, temperature-resistant, easy to apply, simple to apply, and have the ability to form strong bonds. Lucky for you, all the products we’ve included in this article meet all these requirements.

FURTHER READ: