Many types of adhesives form powerful bonds between various materials. However, in some cases, the best contact cement may be the only effective bonding product. Thanks to its ability to adhere to many surfaces, including non-porous materials.

Contact cement is an all-purpose neoprene rubber glue that forms flexible permanent bonds. Besides, it bonds almost instantly, even without clamping the bonded materials. It has high moisture resistance and works on materials that can’t adhere to other adhesives. They’re suitable for leather, rubber, glass, plastics, veneers, countertops, and laminates.

In Hurry! Then Check Our Top 5 Picks:

Similar to other products though, there is a wide selection of contact cement to choose from. Yet not every product will work best for you. Well, take it easy! In this guide, we’ve listed the top 10 contact cement at the moment and their exceptional features.

Check them out!

Table of Contents

The 10 Best Contact Cement Reviews

1. Elmer’s E1012 China & Glass Cement

Elmer’s Products, Inc. is one of the most reputable manufacturers of adhesive solutions in the market today. Although that’s not surprising seeing that they’ve been around for over 65 years. More notably, they produce high-quality, effective, and eco-friendly products. And this E1012 china & glass contact cement is no different!

To start, this glue contains non-toxic ingredients. So it will not harm the environment, kids, or pets. Besides, this makes it safe for indoor as well as outdoor applications. On top of that, it’s dishwasher safe for drying, making it suitable for use in household items. For instance, you can use it to bond china, ceramics, pottery, glass, and porcelain.

As for application, this formula is quite simple to use on any surface. Better still, the adhesive takes just 1 minute to set. Nonetheless, for the adhesive to achieve its full strength, it requires about 2 to 3 days. Therefore, you’ll have enough time to adjust or align the bonded pieces.

All in all, this solvent-free adhesive is a great choice for various tasks. Even though its bond is not instant, it’s the strongest contact cement when it cures fully, so it’s worth the wait. Moreover, this adhesive dries clear and it’s completely waterproof on drying.

Highlighted Features

- Takes 2 – 3 days to cure fully

- Sets in 1 minute

- Waterproof on drying

- Non-toxic, food-safe & dishwasher safe

- Ideal for glass, ceramic, china, and pottery

2. Barge 022721 All-Purpose Cement for shoes

Like the contact cement we’ve looked at above, Barge adhesive has been around for several years now. So, if you’re looking for a popular and reputable contact cement, it would be an excellent option. Moreover, it’s considered the best contact cement for rubber surfaces. It’s very effective in repairing boots, shoe soles, and related parts.

That, however, doesn’t mean that this contact cement will only work on rubber surfaces. Instead, there are many materials out there that this cement adheres to. As an example, it’s ideal for use on glass, metal, wood, leather, and many other types of materials.

Another incredible feature is that this formula is strong and flexible. Even better, it’s waterproof and fairly simple to use, provided the surface is dry and clean. And apply a uniform coat to both surfaces and spread or brush the adhesive to prevent puddling. Finally, let it sit for about 15 minutes and press the surfaces together. Now, leave the surfaces overnight for the glue to cure.

Note, the gallon and quarts Barge all-purpose contact cement contain toluene. So, unless you run a licensed business, you’ll not be sold this product if you live in California. Also, wear a breathing mask during application since this formula has a strong smell.

Highlighted Features

- Includes an applicator brush

- Comes in a 32 oz. (1 quart) can

- Professional strength adhesive

- Works on various materials (vinyl, leather & rubber)

- Suitable for repairing rubber boots, leather sandals, and more

3. Rutland Products Stove and Gasket Cement

Rutland is a reputable family-owned business based in Vermont that was established in 1883. They’re well-known for manufacturing various fireplace products. Basically, if you want anything to clean, repair or maintain your hearths, fireplaces and chimneys, Rutland is your go-to brand.

Also, they manufacture quality soot removers, stove door replacement gaskets, and fire starters. More notably, they’ve some of the best contact adhesives for fire features.

For starters, this contact cement’s ability to withstand high temperatures is outstanding. To be precise, it can tolerate temperatures of up to 2000 deg F. on drying. It adheres to various kinds of gasket materials such as metal and fiberglass. This makes it ideal for making metal to masonry or metal to metal repairs and making stoves airtight.

As for the packaging, this contact cement comes in 2.3 oz. squeeze tube. However, it’s also available in 10.3 oz. cartridge for a large project. Regardless of the option you choose, applying the adhesive to your stove will be very simple. Best of all, you can easily clean up the glue with water even after it has dried.

One thing you need to note though is that this formula requires heat for the curing process to take place. Nonetheless, it’s such a great product to help you create a long-lasting fireplace.

Highlighted Features

- Paintable after curing

- Ideal for indoor application only

- Bonds to metal, steel, cast iron, and fiberglass gaskets

- 2000 deg F. temperature rating

- 1/8” (2.3 oz.) bead can cover up to 29’

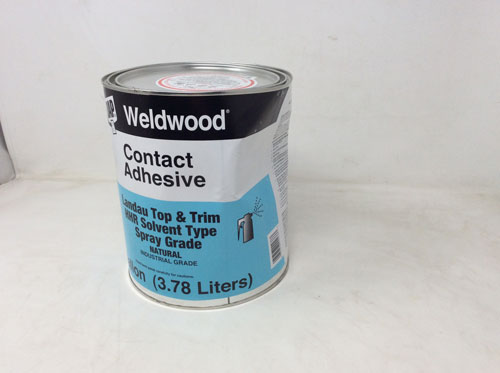

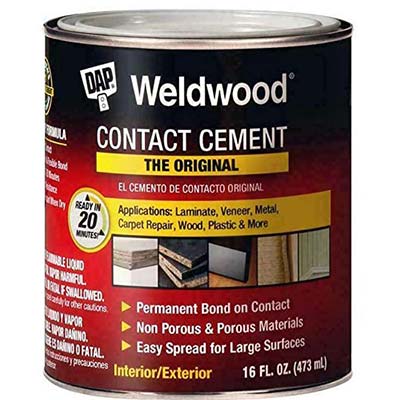

4. DAP 00271 Weldwood Contact Cement

Some adhesives take a long time to set or create strong bonds with the surfaces. As a result, you’re forced to use temporary fasteners or clamps before the adhesive sets. Interestingly, with this original contact cement from DAP, that will not be the case. Instead, this contact adhesive forms permanent, water-resistant bonds instantly.

As if that’s not enough, this formula doesn’t create a mess, run, or drip. Thanks to its easy-to-spread gel formula which makes it simple to apply. Besides, this allows you to comfortably apply it on vertical as well as overhead surfaces.

Talking of surfaces, this glue is compatible with almost every material out there. It bonds with fiberglass, plywood, wood, vinyl glass, drywall, fabric, and fiberboard. More notably, it’s considered the best contact cement for laminate surfaces.

Getting back to the formula, this solvent-based adhesive is made up of neoprene. Moreover, it has a high initial grab and strength, making it suitable for most projects. Not to forget that this formula dries fast since it takes about 15 to 20 minutes.

On curing, the adhesive can resist water and temperatures of up to 180 deg. Fahrenheit. On the same note, it resists household chemicals, weather elements, oil, and grease.

Highlighted Features

- Forms instant and permanent strong bonds

- Works on various surfaces

- Provides high water- & heat-resistance

- 15 to 20 minutes drying times

- Meets all CPSC requirements

- Ideal for use countertops and laminates

- Suitable for indoor & outdoor applications

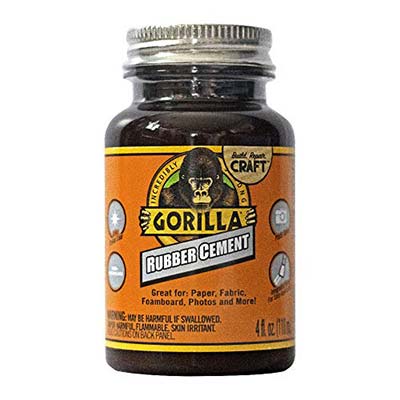

5. Gorilla Rubber Cement for EVA foam

Gorilla was established less than 25 years ago. Yet it’s one of the most reputable manufacturers of adhesive solutions. The company is popularly known for its Gorilla Glue. However, they manufacture various products like epoxies, tapes, and other adhesives. One of those adhesives is this Gorilla Rubber Cement.

One major benefit of this particular adhesive is that it forms a durable bond. Yet it doesn’t yellow or wrinkle after being exposed to various elements over time. For that, it’s considered great contact cement for various crafting projects. More notably, it can be used by both experienced and amateur artists.

Moving on, this acid-free formula creates a flexible and repositionable bond. Hence making it suitable for use on fabrics, photos, paper, and foam board among others. So, if you’re looking for the best contact cement for EVA foam, Gorilla rubber cement is a great option.

As for application, the two 4 oz. bottles are accompanied by a brush applicator. That way, you can smoothly apply the adhesive on the surfaces and rub it off cleanly with ease if needed.

On curing, the cement forms a crystal clear, permanent bond. This means that you’ll hardly see the adhesive once it dries. For that reason, you can conveniently use it on paintings and in collages or scrapbooking.

Lastly, this particular contact cement is 100% waterproof on curing. Therefore, you can either use it for outdoor or indoor applications.

Highlighted Features

- Dries crystal clear

- Comes with a brush applicator

- Ideal for use on photos, fabric, paper & foam board

- Outdoor & indoor application

- Resists wrinkling & yellowing

6. Rutland Products Cartridge Furnace Cement

As we stated earlier, Rutland has some of the best products for fireplace surfaces. However, the Rutland contact cement we looked at earlier can only cover a maximum of 29’ with a 1/8” bead. In other words, it will not be enough to handle a large project. In that case, you’ll need an adhesive with a larger capacity. Well, that’s where this Cartridge furnace cement comes in!

First, this contact adhesive comes in 10.3 oz. cartridge can. Even better, this can contain enough adhesive to cover up to 99” with a 1/8” bead. This packaging plus the ready-to-use formula will make it extremely simple to apply.

Talking of application, knead the caulk tube before use if you intend to handle small repairs. Then cut the tube tip and lightly dampen the surfaces with water. Next, apply the adhesive in 1/8-inch layers and leave it for about 1 hour to air dry.

Finally, start a fire within 30 days and raise the temperature to 500 deg Fahrenheit. This will allow the cement to cure since heat is required for that to happen.

Knowing these simple steps will help you reset firebricks, glue ceramic logs, and repair furnaces with ease. Besides, this cement adheres to several materials including firebricks, stone, and metal.

Interestingly, the cured adhesive will not contract or expand due to temperature changes. Besides, it can tolerate extreme temperatures of up to 2000 deg Fahrenheit. These factors ensure that the cement creates a permanent air and smoke-tight seal.

Highlighted Features

- Easy to clean up and use

- 2000 deg F temperature tolerance

- Ideal for big rebuilds and small repairs

- Intended for indoor applications only

7. RH Adhesives HH-66 Vinyl Cement

HH-66 is considered one of the most effective adhesives for PVC vinyl in the world. Hence its popularity among experts to bond vinyl-laminated and vinyl-coated fabrics.

Also, it forms permanent bonds in inflatable watercraft, geosynthetics, and commercial tarps. On the same note, it’s ideal for bonding vinyl foams, metals, leathers, and urethanes. This formula sets in minutes, even at extreme temperatures. Not to forget that it’s waterproof contact cement, so you can use it underwater as well.

Another benefit of HH-66 is that it dries hard, but remains flexible. Better still, it’s highly resistant to grease, oil, fuel, and most chemicals out there. And its ability to withstand extreme temperatures and weather elements is incredible.

Therefore, you can apply it at any temperature, even if you live in an area with the coldest climate. The only issue with applying it in extremely low temperatures is that it takes a longer time to cure.

There are various forms of applying this vinyl cement to surfaces. For instance, you can either use a squeeze bottle, roller or brush. Besides, you just need to apply a single coat to each surface and you’re good to go.

As a drawback, this solvent-synthetic adhesive dries yellow when used to seal seams. For that, it can easily cause discoloration, especially if applied in white vinyl.

Highlighted Features

- Dries in minutes

- Superior bond strength

- Incredible resistance to severe temperatures, weather, oil, grease, and chemicals

- Convenient application by roller or brush

- Versatile use

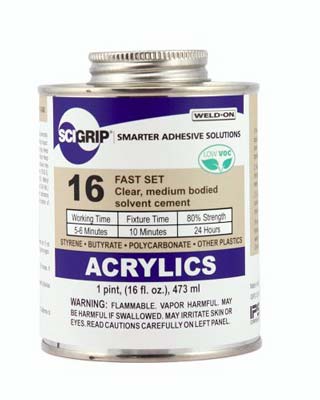

8. SCIGRIP 16 Acrylic Cement

SCIGRIP 16 is another incredible option, especially if you want a high-strength solvent contact cement. However, as the name suggests, this product isn’t a regular adhesive that just bonds 2 surfaces. Instead, it’s an acrylic cement, meaning that it’s intended for use in acrylic sheets. But you can also use it on other plastics such as ABS, Styrene, polycarbonate, and butyrate.

Apart from that, this acrylic cement has many superior qualities. To start, its formula contains low levels of volatile organic compounds (VOCs). Therefore, it doesn’t emit airborne particles that can harm your health. You still need to be cautious when applying it since it contains strong chemicals.

This adhesive starts to dry within the first 5 to 6 minutes of application. And within the first 24 hours, it will have achieved 80% strength. Best of all, when the glue dries fully, it will be as safe as acrylic itself!

SCIGRIP 16 acrylic cement is available in a 1 pint (16 oz.) bottle. So, you’ll get enough adhesive to handle a large project. But as I already mentioned, this high-strength solvent contains strong chemicals.

It contains Methyl Ethyl Ketone, Dichloromethane, Methyl Acetate, and Methyl Methacrylate Monomer. Other than that, it’s easy to apply and sets fast on the surface. Also, it doesn’t leave yellowish residues on drying.

Highlighted Features

- Dries clear on the surface without leaving residues

- Works on different types of plastics and acrylic

- Withstand water, temperature, and humidity

- Fast fixture and working time

- High-strength, fast-setting adhesive

9. IPS Weld-On 3 Acrylic Cement for plastic

Since acrylic is a shock-resistant and strong material, regular adhesives don’t adhere to it. That’s why you need a special adhesive like IPS Weld-On 3 cement when you’re dealing with acrylics. Thanks to its exceptional ability to melt and rejoin various types of acrylics.

Simply put, IPS Weld-On cement will soften the acrylic surface on application. Then join or ‘weld’ them together as the name suggests. 24 hours later, the adhesives will have gained 80% strength.

That aside, this formula comes in 4 oz. can. Unfortunately, applying this adhesive directly from them can be quite messy. Don’t worry though, as the package comes with a convenient bottle with a needle to help you avoid that. Moreover, this will allow you to apply the adhesive in tight spots without spilling it.

Another factor that makes this adhesive simple to apply is that it has a water-thin formula. Not to forget that it has a 1-min working time and 2-min fixture times.

Finally, this glue is quite versatile, so you can use it on other materials apart from acrylic. As an example, you can apply it to polycarbonates, butyrate, and styrene. Besides, it doesn’t leave residues on drying.

Hence making it ideal for various industrial and DIY applications. With that in mind, it’s safe to use in headlights, fish tanks as well as display cases.

Highlighted Features

- Includes an applicator bottle with needle for precise application

- Water thin formula

- Bonds within minutes after application

- Adheres well to acrylic and other polycarbonates

- Doesn’t leave white residues on drying

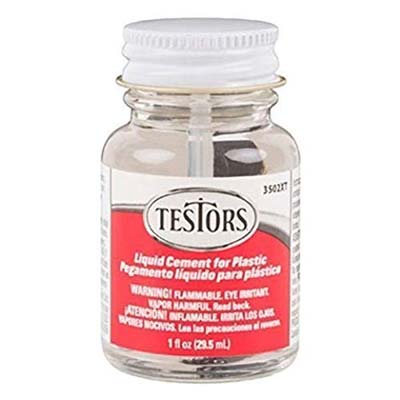

10. TESTORS CORPORATION 3502XT Plastic Cement

Since its establishment in 1929, Testors Corp. has been associated with integrity and quality. Something that is reflected in all their products including their cement adhesives. Moreover, their adhesives are exceptionally strong, easy to use, and fast-drying. Best of all, they provide convenience and quality, yet they’re reasonably priced. With this 3502XR being one of their top contact cement for different kinds of plastics.

That said, let’s check out some of the outstanding properties of this cement adhesive!

At first glance, 3502XT liquid cement comes in 1 oz. glass bottle. Like the plastic cement we’ve reviewed above, this formula weld surfaces together. In other words, it dissolves plastic to create a bond. However, it’s much thicker than the IPS Weld-On cement, so it will not run quite as much.

In terms of versatility, this adhesive works on several kinds of plastics. It’s ideal for use on ABS plastic, plexiglass, polystyrene, and acetate among others. After that, the glue dries fast to form a strong bond. More notably, it can withstand various solvents, heat, and water.

On the downside, the glass bottle’s cap isn’t threaded, so it can easily pull on and off. Also, the package doesn’t include a precision applicator cap. This can lead to a messy application. Other than that, it’s one of the best types of adhesives to use on various types of plastics.

Highlighted Features

- Works on all plastics

- Fast-drying formula

- Resists solvents, heat, and water on drying

- Forms a strong bond

- Comes in 1 oz. glass bottle

What to look for before buying a contact cement

Choosing the right contact cement usually depends on the surface you want to repair or bond. However, there are many other factors you need to put into consideration as well. Some of those factors are;

Type of contact adhesive

A particular adhesive may work exceptionally well on a certain material as compared to another surface. For instance, super glue adheres well to leather, glass, ceramic, and even wood. But when it comes to acrylic, it doesn’t work that well. On the same note, it may even leave white residue on acrylic surfaces once it dries.

Besides, there are many types of contact adhesives out there. They include; epoxy adhesives, cyanoacrylates, structural acrylic adhesives, and UV curable glues. In essence, adhesives have different properties and they’re intended for various applications.

So, before you settle on certain contact cement, look at the materials it works on, its type, and features. Otherwise, you may end up with a product that isn’t suited for your project.

Adhesive resistance

The best contact cement should’ve outstanding resistance to extreme heat, cold, and water. That way, it will hold up when exposed to severe temperatures and weather elements. On top of that, it should withstand chemical attacks to extend the longevity of your items.

Curing & setting time

Curing time is the time the contact cement takes to dry. This duration tends to vary from one adhesive to another. As an example, some glues may take minutes to dry, while others may take days. Also, some products offer instant bonds, while others become stronger over time.

In essence, if you’re in a hurry, choose a contact cement with fast curing and setting time. But if you prefer a permanent and strong bond, choose an adhesive with a longer curing time.

Color

Lastly, pay close attention to the color of the contact cement after it dries. There are transparent (clear) and colored adhesives in the market. Unfortunately, some of these products tend to leave yellow or white residues on drying.

This can affect the strength of the adhesive and its aesthetic appearance. So, make sure you select a glue that doesn’t surface residue when it dries.

Frequently Asked Questions

#1. Is contact cement waterproof?

Most general-purpose contact adhesives tend to be waterproof and water-resistant on drying. This makes them ideal for outdoor and indoor applications.

#2. How long does it take for contact cement to dry?

Contact cement becomes touch to dry after about 10 to 60 minutes. However, it’s recommended that you bond the surfaces within 30 minutes after applying the adhesive.

#3. What is stronger than contact cement?

Epoxy adhesives are much stronger than contact cement. Besides, epoxies have higher resistance to solvents, impact, UV light, and high temperatures.

#4. What kind of cement is used for shoes?

Shoe manufacturers usually use neoprene cement to bond the bottom of the shoe and the sole. Thanks to its ability to provide a strong, waterproof permanent bond.

#5. How do you spread contact cement for laminate?

Using a roller is the easiest way to spread contact cement on laminate surfaces. However, not every roller will get that task done. For instance, you should avoid short-nap or foam rollers since it’s difficult to remove the adhesive residues from them. Instead, choose a solid roller, preferably with some type of hard rubbery material.

Conclusion

Having the best contact cement will help you bond surfaces that regular glues don’t adhere to. That usually happens to smooth surfaces, since their bonds tend to degrade over time.

Thankfully, provided you’ve selected the right contact cement, you’ll not experience those problems. Besides, contact adhesives form permanent, strong, and durable bonds with almost any material.

Note, some of those formulas emit fumes that can cause headaches or irritate your lungs. So, ensure you work in a space with proper ventilation when handling these products.

Up Next: Best Adhesive for Concrete