A drill press is one of the most essential tools for your workshop. It’s used for boring holes through different materials, and it can also be used for drilling angled holes. This tool is a must-have if you’re doing woodworking or metalwork regularly.

The question of how high the bench should depend on what type of drill press you have. If you have a floor-standing drill press, it should be at the height that feels most comfortable to you.

If you have a benchtop model, however, it’s important to mention that there is no universal standard when it comes to the height of your benchtop. You need to adjust it according to your own needs and preferences.

In this article, we will take a look at how high a drill press should be and other related questions that are often asked by those who are looking for this information.

Table of Contents

What Height Should a Drill Press Table Be?

A drill press table is an essential part of a drill press. The table ensures the precision and accuracy of your work by holding the material you are working on in place. It also protects your workpiece from the drill bit.

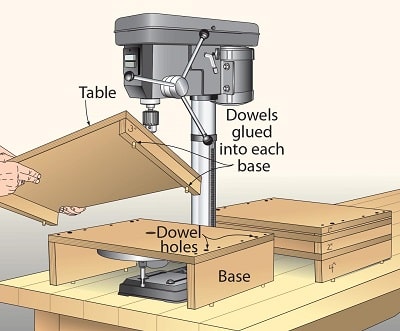

The base of a drill press is what holds the entire unit in place. These two parts are very important and have to be carefully chosen based on the requirements of your project.

The height of a drill press table should be just above the level of your waste if you are standing upright. This will ensure that you can easily operate it without straining your back or shoulders.

A drill press table can be made taller by placing some blocks under each leg of the stand, but this should only be done if absolutely necessary as it may affect the accuracy of your work. If you do need to make your table taller, try adding one block first before going all out with three blocks (or more).

You can adjust the height of the drill press table by loosening the wing nuts, raising or lowering the table to the desired height, and then tightening the wing nuts back into place.

You don’t need a drill press table, but it’s recommended for better control over your projects and to keep them safe from being damaged by the bit while drilling holes in them (and other things like that).

The base on a drill press is what holds the entire unit in place and makes sure it doesn’t fall over or wobble while working.

How Do You Make a Drill Press Taller?

The height of your drill press table is dependent on a variety of factors. The most important factor is the kind of work you plan to do with it. If you are going to be working with smaller pieces, then a basic height will suit your needs. If you plan on working with larger items, such as tables or even chairs, then a taller model will be required.

The next thing to consider is the size of your workspace and whether it is large enough for the height that you need. If it is not, then you will need to purchase an additional tabletop or use something like a stool or chair to increase the height of the table.

Another important consideration is how much weight you want your drill press table to hold. You should always keep in mind that wood tends to expand and contract with changes in temperature and humidity.

This means that if you live in an area where there are high temperatures and humidity levels, then you should get one that can hold more weight than if you live in an area where there are low temperatures and humidity levels.

Do You Need a Drill Press Table?

While there are several ways to improve the accuracy of your drilling, a drill press table is one of the most common ways. A drill press table will not only add stability to your workpiece, but it will also allow you to create more accurate holes by using a fence and clamps.

The good news is that you don’t have to purchase an expensive drill press table. You can make one yourself with some scrap wood and a couple of hours of time.

What Is The Base On a Drill Press?

The base on a drill press is where you mount your tool to a workbench or stand. The base on a drill press is what holds the entire unit in place and makes sure it doesn’t fall over or wobble while working.

The main purpose of the base is to support the unit and provide clearance for any bits that extend below the table surface. Some bases also have holes and slots.

What Is The best Height for a Drill Press?

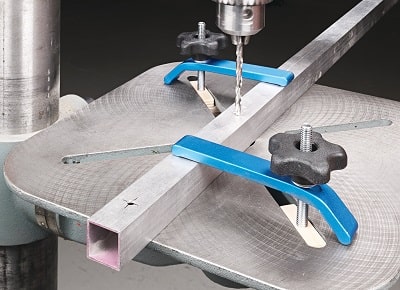

The best height for a drill press depends on the work that you are going to do. For most metalwork, you should position your platform so the spindle of your drill is just over the center of your workpiece.

This will allow you to have maximum control when operating the tool. The chuck should be at a height where you can easily reach it without having to strain your back.

The height at which you use your drill press depends on how tall you are and what type of work you do. You may want to experiment with different heights until you find one that works best for your needs.

If you are using a drill press that has been designed to be used while sitting on the floor, then it should be at least 6 inches off the ground when not being used. If it is too low, you may find it hard to reach certain parts of the workpiece or get good leverage when drilling holes in larger pieces of wood or metal.

You can also use your drill press for other types of drilling if necessary, but this may require some adjustments to its height. If you need more leverage when drilling holes in thicker materials like steel, then consider purchasing a higher one.

Do Drill Presses Need To Be Fastened To The Floor?

They do not need to be bolted down, but doing so is strongly recommended. If there are children in your home, a bolted-down machine will prevent them from moving it around.

Additionally, if you plan on working with large pieces of wood or metal, securing it will keep it from shaking and shaking as you work. It is also a good idea to make sure that the machine is level so that it operates properly and does not damage itself over time.

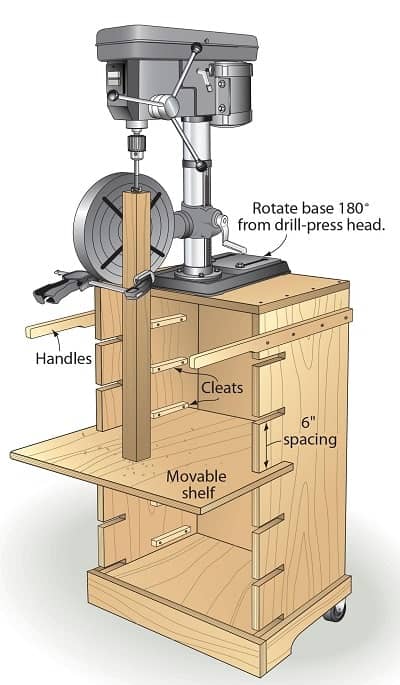

A drill press is a fixed style of drill that may be mounted on a stand or bolted to the floor or workbench. A drill press consists of a base, column (or pillar), table, spindle (or quill), and drill head, usually driven by an induction motor.

The head has a set of handles (usually 3) radiating from a central hub that, when turned, move the spindle and chuck vertically, parallel to the axis of the column.

The base is made of cast iron and contains slots and holes for mounting to the floor and workbench. Sometimes it has a coolant reservoir and tank and a chip tray, depending on the type of coolant system used.

The column is attached to the base and contains the motor drive mechanism and controls; it may house coolant plumbing if used.

For bench-mounted drills, the column is often integrated into the base casting. The table sits atop the column and provides support for the work piece during drilling.

Tables can tilt left or right up to 45 degrees for angled drilling operations. The table may also have a provision for clamping the work piece in position.

How High Should a Drill Be On a Bench Stand?

This depends on how tall you are and what type of work you want to do. If you are taller than average, then keeping your benchtop around 36 inches will allow for more space between your machine and your body when operating it.

The height of the drill press will depend on the type of work you are doing. You need to consider the depth of the drill, which will determine the height. If you are drilling deep holes, then you need a high drill press. If you only want a thin hole, then you can use a low drill press.

For small projects, a bench stand is all you need. For large projects, a larger stand is more appropriate.

You do not need to fasten your drill press to the floor. It is okay for it to rest on the table or bench top.

Why Does a Drill Press Base Have Slots?

The base of the drill press is one of the most important parts. It holds the motor and chuck and keeps them in place while you work. The base also serves as a work surface for your projects, allowing you to use it as a table or to hold bits and other tools.

The base is usually made of cast iron or steel. The metal provides a sturdy platform that is heavy enough to keep the drill press in one place but light enough for you to move it if needed.

Most models have slots in the base that let you attach accessories such as fences, stops, and lighting. These slots are often T-shaped so they can be adjusted easily by loosening a set screw and moving the accessory left or right.

Frequently Asking Question

1. Do You Need a Drill Press Table?

Drill Press Table is a table that is attached to the drill press to make drilling easier and more efficient. The drill press table serves as extra support for the material being drilled, which makes it easier to produce consistent hole sizes and accurate depth placement.

It also provides a secure surface for the material and makes it easy to adjust the height of the material.

2. What Is The Base On a Drill Press?

The base is the bottom part of the drill press table. It is usually made of cast iron, but you can also find a base made out of aluminum or steel depending on how expensive your drill press table is.

A drill press base has slots and holes where you can attach different attachments like feather boards, fence or stop blocks so you can customize your drill press table according to what you need.

3. What Is a Drill Stand?

A drill stand is a temporary stand used when drilling holes on materials like wood, metal or plastic. The main purpose of a drill stand is to hold the material in place while drilling.

You can use clamps or screws to attach the material to the stand, but sometimes, you don’t need anything at all because there are already some holes on the base of your drill stand that you can use for this.

4. How Do You Bolt a Vise To a Drill Press?

To bolt a vise to a drill press, you need:

A bolt that is longer than the thickness of the plate that you are securing the vise to. You will also need to mount the vise on top of the plate so that it is level with the top of the plate.

Make sure that you have enough room for the bolt to go through both sides of the plate and into the hole in the vise. You can use a small hole in one side of the plate, or you can use two bolts on each side of the plate if you want to make sure that there is enough clearance for your bolt.

Wrap Up

Drill presses come in a variety of sizes and types. The size of the work piece you will be drilling will determine what size drill press you need. There are basically two types of drill presses, benchtop, and floor standing models.

Bench Top models are usually used for drilling small to medium-sized pieces. They typically have a swing of 12 inches or less and capacity from 1/2″ to 3/4″ in steel.

Floor-standing models can be used for drilling large pieces as well as small pieces. They typically have a swing of 18 inches or more and capacity from 1″ to 2″ or larger.