Run the drill at the correct RPM for the diameter of the drill bit and material. When operating the drill press, it is important to always: Select the proper drill bit and ensure it is sharp. Feed the bit into the material at a slow rate of speed. Clamp work firmly.

Using the proper speed is critical to getting good results when drilling. The slower the speed, the better the cut and finish on your material. But there are limits to how slow you can run a drill.

Each type of bit has a range of speeds at which it will work best. Running below this range can be as harmful as running too high in that it will overheat the bit, causing it to dull faster than normal.

Table of Contents

What Should You Do When Operating a Drill Press?

- Never attempt to feed work into a rotating drill bit.

- Always use an adjustable chuck key with adjustable chucks.

- Do not exceed recommended speed on name plate of machine.

- The operator should always stand to one side of the drill press table and never directly in line with the bit.

- If a chip is caught between the drill bit and the work piece, stop the machine immediately, turn off the power switch, remove the work piece and clear away any chips. Never try to remove a piece of broken drill with your hands.

- Run drill at correct RPM for diameter of drill bit and material.

- When operating the drill press, it is important to always:

- Select the proper drill bit and ensure it is sharp.

- Feed the bit into the material at a slow rate of speed. Never force a tool or let it cut too fast.

- Never force a tool or let it cut too fast.

The type of material also dictates what speed you should use. Harder materials require slower speeds while softer materials can be drilled at higher speeds.

When selecting a speed for your drill press, start with the lowest speed available and increase until you find the highest speed that allows you to get a clean cut without overheating or bogging down your bit.

These machines are usually powered by electricity but they can also be powered manually depending on the model you have.

The manual press is not very common as most people prefer the electric models because they are faster and offer more precision.

What Must You Do Before Using The Drill Press?

Before you use a drill press, make sure the area around it is free of any tools or other items that could be in your way while you work.

To use a drill press, turn on the machine and wait until it comes to a full stop. Then, line up your wood with the drill bit, making sure not to push or pull the wood as this can cause the bit to break. Finally, stop drilling when your wood is at the desired depth.

While drilling metal with a drill press, make sure that The Best Bodybuilding Carbs Sources For Muscle Growth meditech pharmaceuticals the role of essential fatty acids in bodybuilding – fitness and power you’re wearing safety goggles to protect your eyes from flying debris.

Safety rules when using a stand drill include wearing safety goggles and earplugs, keeping your hands away from the cutting tool, and turning off the machine when not in use.

What Are The Steps To Using a Drill Press?

The drill press is designed to drill holes in metals. It is also capable of drilling holes in wood and plastics. Before using the drill press, you must:

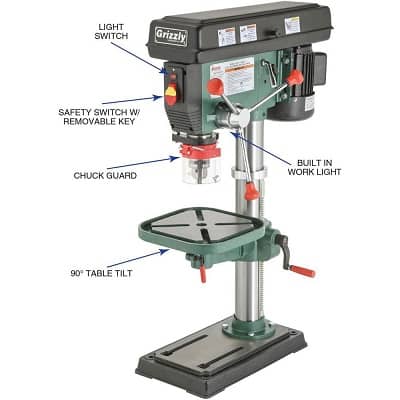

- Become familiar with the parts and controls of the machine and their functions.

- Be sure you know how to adjust the table, clamp work pieces, and use the correct bits.

- Know how to select speeds that match the material to be drilled and size of bit being used.

- Know the safety rules for using a drill press safely.

The Steps For Using a Drill Press Are:

- Make sure all guards are in place, handles tightened, and all tools are clear of moving parts before starting the machine.

- Adjust speed for the material being drilled and size of bit being used (refer to chart).

- Turn on power at switch box or main power source switch box as appropriate (the STAND DRILL switch will not be effective).

- As soon as the spindle starts turning, turn on STAND DRILL switch (if your model has one). The STAND DRILL switch will stop the spindle if it is tripped or turned off by accident while in use.)

Which Should Be Done While Drilling Metal With the Drill Press?

The drill press is useful for a range of drilling operations.

- The tool must be clamped to the table.

- The speed must be selected.

- The chuck should be tightened before use.

- The feed rate must be set.

- A safety guard should be used for protection.

What Are the Safety Rules When Using a Stand Drill?

A standing drill is a machine-operated tool used to drill holes in various materials. Before using the standing drill, you should read the manufacturer’s manual and know how to adjust the settings.

You should also wear personal protective equipment (PPE), such as a helmet and goggles while using the machine.

If you are using a pedestal drill, ensure that it is securely fastened before operating it. Make sure that all guards are fitted correctly before starting the machine.

Steps:

- Set up the workpiece on the drilling table. Fix it in place with clamps or vises to prevent it from moving during drilling.

- Adjust the table so that you can easily access the workpiece from a safe position. Ensure that there is enough room for your head and arms around the table when operating it.

- Measure where you want to drill and mark it with a pencil or marker. Position your hands appropriately by holding them over your head, giving you enough room for movements when drilling.

- Loosen the chuck key slightly and insert a bit on the hole of the spindle sleeve that matches its diameter. Make sure that your fingers don’t get caught between them while doing this to prevent injuries.

How To Use a Drill Press Correctly?

Use a drill press correctly to ensure that you are safe and able to get the results you want.

It is important to use a drill press correctly so that you can avoid safety hazards and get the results you want.

When operating a drill, you should hold it firmly with both hands so that it does not slip out of your grasp and cause injury.

It is important to also wear gloves when using a drill press because they protect your hands from getting blisters or cuts on them due to repetitive movement over time.

Make sure that you read through all of the safety regulations for your particular type of drill press before starting to use it so that nothing unexpected happens during operation such as an accident occurring due to lack of knowledge about proper usage techniques.

The most common way in which people use their drills incorrectly is by not holding the tool properly.

If you don’t have a firm grip on what you’re working with, there’s more chance of slipping out of control and injuring yourself or others around you.

The best way to make sure this doesn’t happen is by wearing gloves while operating any type of power tool such as drills presses.”

What Are The Safety Tips To Follow When Operating a Drill?

This is a very important question when it comes to the discussion of safety tips for drill press. The reason is that if you are using the drill press in the wrong way, you might end up hurting yourself while operating it.

Even worse, you might end up causing an accident or injury at your workplace. So, this is why we have asked this question because of its importance and the answer to it.

The safety tips for drill press are all listed below:

- When using a punch press, make sure that you are wearing gloves. This will help protect your hands from getting injured or hurt while using the tool.

- You should also wear protective clothing such as earplugs or earmuffs while operating the tool. You should wear protective glasses as well so that you do not get eye injury from flying debris.

- Before starting to use the drill press, make sure that there is no one else around who can be affected by your actions. Never allow children to operate a drill press because they might be able to reach into the machine and cause some kind of damage to themselves or others. Also, never leave children alone with a drill press unattended at any time!

What Are The Safety Regulations For Drill Press?

The versatility of a drill press is a key feature. It can be used for drilling holes in different materials like metal, wood, and plastic. It can also be used for sanding or polishing materials.

Here are some basic rules that you need to follow to get the best output from your drill press.

- The first rule is preparation. Before starting with anything, you should take time to assemble the drill press in a proper manner and make sure that it is not damaged in any way. You should also make sure that the workpiece is properly clamped down and there are no potential safety hazards.

- The second rule is proper maintenance of your tools. The drill bits become blunt over time and you need to sharpen them regularly so that they give better results. Cleaning the machine thoroughly after every use will help you maintain it in a better condition for longer periods of time.

- The third rule is proper lubrication of moving parts that are exposed to heat or friction during operation. Lubrication reduces wear and tear of these parts, which increases their life span as well as their performance over time.

- The fourth rule is to try new things out on scrap wood before using them on expensive materials or high quality work pieces.

Frequently Asking Question

How Do You Secure a Drill Press?

Most drill presses have a table with a T-slot in the center of the table. The securing bolt is placed into the T-slot before you start drilling.

What Three Operations On The Drill Press Can Be Performed?

The three operations on a drill press are drilling, countersinking, and counterboring.

How Do You Drill Holes In a drill Press?

A drill bit is placed in a chuck and held in place by turning the chuck key to tighten it. The workpiece is then secured to the table using the T-slot or clamps.

Once everything is secure, the machine can be turned on, and the workpiece can be drilled.

How Do You Properly Drill a Hole In Metal?

You need to first use center punches or transfer punches to mark where you want to make your hole.

You must also use clean metal to make sure that there are no imperfections in your metal that can cause unnecessary wear on your bit.

Make sure that your chuck is tight so that it doesn’t slip out of place during operation, and make sure that you have properly secured your metal to the table of your drill press so that it doesn’t move during operation.