The best speed for drilling wood depends on the diameter of the bit and the material drilled. Larger diameter bits require a slower speed, as do hardwoods.

Drilling into softwood with a twist drill bit up to 3/8″ in diameter requires a speed of 3000 RPM, while the same bit with hardwood requires 1500 RPM.

Drilling into softwood with a brad point bit between 1/8″ and 3/8″ in diameter requires between 2000 and 3000 RPM, while the same bit with hardwood needs between 1000 and 2000 RPM.

Drilling into softwood with a brad point bit between 1/4″ and 1/2″ in diameter requires between 1400 and 1800 RPM, while the same bit with hardwood needs between 700 and 900 RPM.

Drilling into softwood with a Forstner bit up to 1-1/8″ in diameter requires between 600 and 800 RPM, while the same bit with hardwood needs between 300 and 400 RPM.

Table of Contents

What Speed Should I Run My Drill Press?

Speed controls on drill presses vary from simple pulleys and belts to electronic variable speed. You can adjust the speed of your drill press to accommodate not only the material you’re drilling but also the bit you’re using.

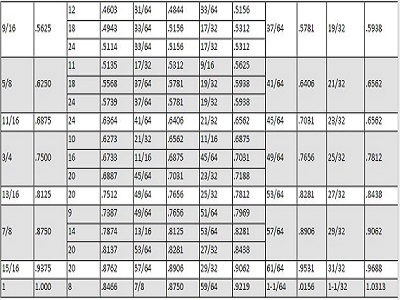

The chart below shows a range of suggested speeds for common materials used in woodworking projects.

Drilling is all about heat, but too much heat can cause problems like burnt drill bits, melted plastic and warped wood. Heat is generated by friction between the cutting edges of the drill bit and the material being drilled.

As speed increases, so does heat; as feed pressure increases, so does heat; and as cutting edge dulls, more heat is generated because more work has to be done to cut through the material.

Note that sharp bits require less pressure than dull ones. That’s why it’s so important to maintain clean, sharp-cutting edges on your bits.

The key to drilling at the proper speed is to use a higher speed when drilling softer materials such as plastic or metals and a slower speed when drilling harder woods.

Also, use a slower speed when using larger-diameter bits because they require more torque than smaller bits do and will overheat if run at high speeds.

Drill press speed controls are generally either mechanical or electronic.

How Is Drill Press Speed Calculated?

Drill press speed is the rate at which the bit rotates, or spins, as it cuts through the material.

It’s important to set the correct drill press speed for each type of material and bit you use. A drill press speed chart can help you determine the correct speed for your tool and workpiece.

Drill press speed is determined by the kind of material you’re drilling and the diameter of the drill bit.

The correct drill press speed for a given bit is determined by multiplying the recommended rate on your chart or in your manual by the diameter of your bit. For example, if your manual recommends a rate of 800 RPMs for a 1/2-inch bit, that means you should set your drill press to a speed around 400 RPMs when using a 1/4-inch bit.

Drill press speed is measured in terms of the rate at which the outside or periphery of the tool moves.

In the case of a drill press, the periphery of the drill bit is its edge, the very edge that cuts into wood or metal as you work.

The faster this edge turns, and the faster it moves against your material, the more efficiently your drill bit cuts.

The calculation for RPM (revolutions per minute) is simple: The formula for calculating RPM is CS x 4 divided by D, where CS is cutting speed, D is the diameter of the workpiece, and 4 is a constant that provides the correct units in rev/min.

Why Is It Important To Adjust The Drill Press To The Correct Speed?

Drill press speed is determined by the kind of material you’re using and the size of the bit. The faster the speed, the hotter the bit gets, so you need to prevent overheating by slowing down when drilling harder materials or larger bits.

When you start drilling, you won’t have much control over the speed, because drill presses don’t have a gearbox like a manual drill.

Instead, they have a belt-driven pulley system that works through ratios: A larger pulley on one shaft will turn a smaller one on another shaft at a higher speed. You can change the speed by moving a lever that alters these ratios.

You’ll also be able to change speeds manually using an electronic control box that lets you adjust RPMs precisely.

Some models also let you preset different speeds manually so you don’t have to keep flipping back and forth as material or bit sizes change.

What Are The Two Types Of Speed Controls Used In Drill Presses?

The most common type of drill press has two belt pulleys that are connected by a belt. These pulleys have a series of grooves in their outer circumference which mate with a series of pins on the motor pulley and on the drive pulley. This allows the user to adjust the speed of the drill press to match the material being drilled.

The speed of a drill press is typically measured in revolutions per minute (RPM). It is important to match the RPM of the drill press to the material being drilled. For example, if you are drilling wood, you want to use a slow speed so that you do not burn up your drill bit. If you are drilling metal, you want to run at a faster speed so that you don’t break your bit.

There are two types of controls for adjusting the speed of a drill press. One type uses a lever that moves pins into different grooves in order to adjust the speed.

On some models, this lever is on one side of the machine while on others it may be located near where you stand when using it.

The other type uses a switch that allows you to select different speeds based on what material you will be drilling.

Is It Better To Drill Fast Or Slow?

The speed at which you drill can vary depending on the material you are drilling. If you are drilling through steel or iron, a high speed is recommended, whereas if you are drilling through wood or plastic, a lower speed should be used.

If you force the drilling process by using too much pressure, then this can cause your drill bit to overheat. This can wear down your drill bit and decrease its lifespan.

A good way to slow down your drill speed is by using a step drill bit. These bits are designed to make holes of different sizes in a range of materials. They have multiple sets of flutes (the spiraling grooves on a drill bit).

The larger flutes will help slow down your drill speed for large holes, and when you get to the small holes, the smaller flutes will increase your drilling speed.

Is Wd40 Good For Drilling?

No, WD-40 is not a good lubricant to use on a drill. It would be much better to use something like an anti-seize lubricant. This is because WD-40 is not a true lubricant.

If you are using a cordless drill, I would recommend charging the battery pack at least once every 2 months.

WD-40 is a great tool to have on hand when drilling. It’s a strong lubricant, so it helps your drill bit spin more quickly and efficiently.

Its special formula also works as a rust preventative, which will help keep the metal parts of your drill press in great condition.

All drill presses have a way of determining the speed of the chuck, but most of them are very similar.

The speed is usually shown by a number that corresponds to a number on the dial that you can turn. For example, if your drill press says “12000 RPM” you will want to set the dial to 12000 RPM.

The speed of a drill press depends on two things: how fast the motor spins and how fast the belt is. A motor can be made to spin at any speed, but it’s not very useful if it has no way of getting power from its source.

If you attach a pulley to the shaft of your drill press, then this pulley would spin at whatever rate you specify with the belt attached to it. This allows for greater control over how fast or slow your machine is running.

How Do I Slow Down My Drill Speed?

When drilling metal, start with a smaller bit and work your way up. A small bit will get the job done faster, saving you time, and will be less frustrating. It is also safer.

A drilling machine is used to drill holes in metals or any other materials. We use it for making a hole for screws, nuts, etc. Drilling is done by rotating a tool called a drill bit which has cutting edges at its end or tip.

When you have the correct speed, you can drill holes faster into the wood and other softer materials with less effort and more precision than you could otherwise achieve.

When drilling through harder materials like steel and aluminum, reducing the speed of your drill press will help keep the bit from overheating while it cuts through the material.

Do You Have a Speed Chart For Drill Bits?

Most drill presses have a speed chart on the front that corresponds to the size of the bit you are using. The larger the bit, the slower the speed.

The smaller the bit, the faster the speed. This is something you will probably get used to overtime and not need to refer to a chart.

Drill bits are made from high-speed steel (HSS) or cobalt steel alloys (most commonly M2 or M35). A couple of other materials used for bits are carbide (usually a ceramic material) and titanium nitride coatings which give more lubricity to the bit.

Most low-speed drill presses operate at 1,725 rpm; mid-range ones at 2,500 rpm; higher-end models at 3,250 rpm and 5,000 rpm; and industrial-grade bench-top drill presses go as high as 5,000 or even 6,000 rpm.

The optimum speed for any drill depends on many factors including material type and thickness as well as whether you are drilling wood, metal, or plastic.

The best way to determine what speeds your machine is capable of is to test it with different tools under varying conditions.

Frequently Asking Question

What Is The Best Rpm for a Drill Press?

The optimum speed varies by the size of the bit and the material you are drilling. For most average jobs around the house, 1500 RPM should suffice.

Wood bits range from 1500-3000 RPM, twist steel bits are usually around 600 RPM, and masonry bits can be as low as 200 RPM.

How To Change The Speed On a Drill Press?

Drill presses have a belt and pulley system that allows you to change speeds by moving a lever or adjusting a tension knob. The higher the number on the tension knob, the slower your drill will spin.

If your machine has numbered settings for each adjustment point, refer to your owner’s manual for specific guidelines.

What Happens If You Drill Too Fast?

It depends on the type of drill bit and material you are drilling into. Some materials need to be drilled at a lower speed. If you are drilling into metals then you want to drill at the highest possible speed. If the metal is harder, then you will want to use a slower speed.

The reason for drilling fast is because it puts less stress on the drill bit and therefore it does not break as easily and will last longer.

Why Is Drill Speed Important?

The material you’re working with will determine what speed is required. The wrong speed can damage your tool, causing bit slippage or breakage which can result in injury, so it’s important not to exceed recommended speeds.

Using too high of a speed can also cause burning and melting of the workpiece. Using too low of a speed can cause bending and breakage of the bit or slow down progress unnecessarily.